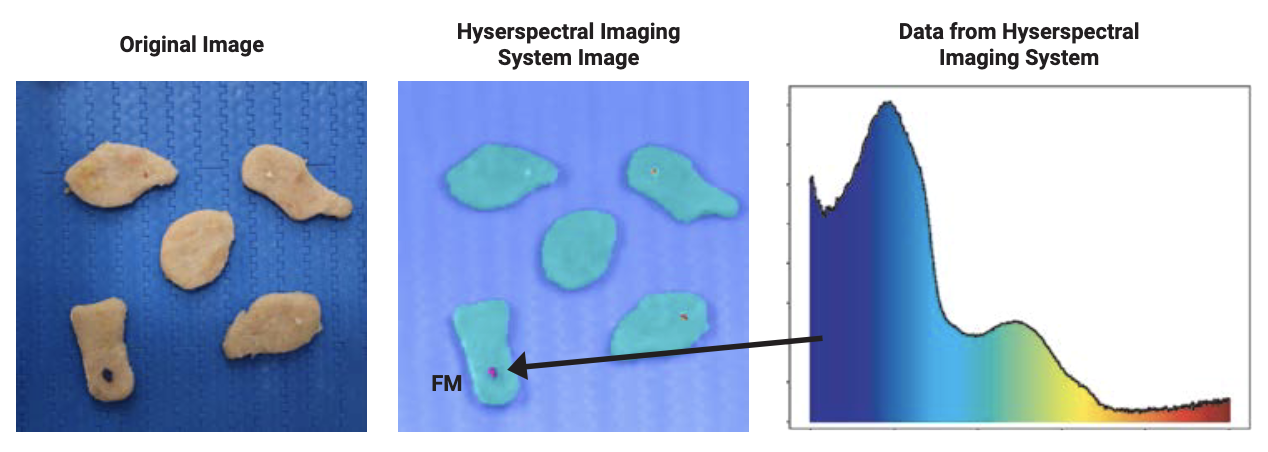

Experience the most advanced and sophisticated system available in the market today. Our bioClass® system utilizes cutting-edge sensors that capture hundreds to thousands of color bands per pixel, surpassing the normal range of human vision. With this immense number of bands, our system has the remarkable ability to differentiate the chemical composition of each pixel, even “learning” new chemical signatures over time. Imagine being able to distinguish between same-colored plastics by detecting variations in their chemical makeup. This level of precision is unmatched.

Unlike other detection systems, our hyperspectral technology offers unparalleled flexibility in identifying a vast array of objects, including those with previously unknown properties. No longer limited by speed or pixel size, recent advancements in detectors and computing power have made hyperspectral inspection feasible for meat and poultry processing applications at line speed. With precise lighting conditions, our bioClass® system ensures accurate and reliable results.

Here’s how our bioClass® Hyperspectral Meat and Poultry Foreign Material Food Safety Detection System stands out:

- Unmatched Resolution: Our system can detect even the smallest particles, with a resolution that surpasses traditional vision systems. By using multiple pixels to resolve objects, we guarantee precise and reliable detection, even in challenging conditions.

- Comprehensive FM Detection: While other systems may only detect objects at or near the product’s surface, our bioClass® system can identify foreign material underneath or on the sides of the product. Through additional imaging heads or product presentation methods, we ensure comprehensive coverage.

- Versatile FM Detection: Differentiating materials is essential for an effective detection system. Our bioClass® system offers three types of detection:a. Camera Detection: Detects objects with significant contrast or color difference from the product. Whether it’s opaque, dark blue plastic or translucent, light-colored plastic, our system delivers exceptional performance. Uniformity of the product doesn’t hinder detection, making it ideal for various scenarios.b. Multispectral Detection: Outperforms camera systems in low-contrast situations by utilizing selected color bands that correspond to the FM’s chemistry. Even if the visual appearance is similar to the background material, our system can differentiate and detect specific materials. Perfect for well-defined processes with known and cataloged FM.c. Hyperspectral Detection: The epitome of low-contrast detection on complex product surfaces. Our hyperspectral system not only captures color but also analyzes the chemical composition of objects. It can even detect translucent materials and thin films. Additionally, our system can flag foreign objects that have never been seen before, solely based on their distinct chemistry. Perfect for scenarios where a wide range of FM or unknown materials may be present.

Discover the future of meat and poultry foreign material detection with bioClass® by Automate and Control LTD. Our system’s unmatched capabilities, combined with its ability to evolve and adapt to your product specifications, make it the ultimate choice for real-time FM detection. Don’t compromise on food safety—choose the industry-leading bioClass® system today!

More information about implementing FM detection strategies. https://www.automateandcontrol.com/?r3d=the-meat-poultry-industry-foreign-material-manual-2021-considerations-for-designing-a-foreign-material-control-prevention-program