- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

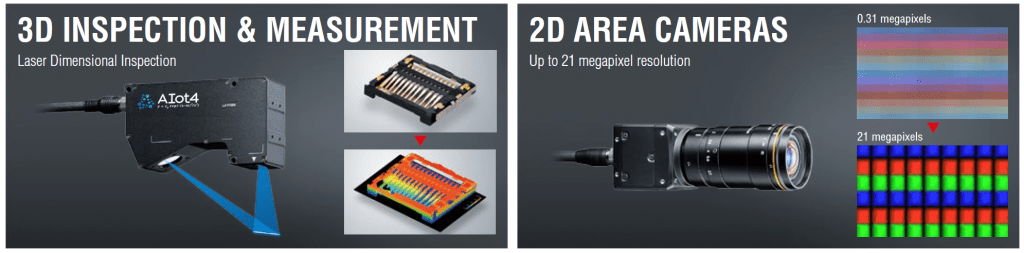

Industrial Vision System Applications & Solutions

Automate and Control LTD bring you the Aiot4 brand of advanced Industrial vision systems. Our systems have overcome the traditional issues related to industrial vision utilising ML and AI taking out the human error side of system setup with intuitive vision tools. Encompassing integrated intelligent lighting, cameras and controllers all coupled with world class latest generation algorithms in our easy to use software.

Area Camera Vision Systems

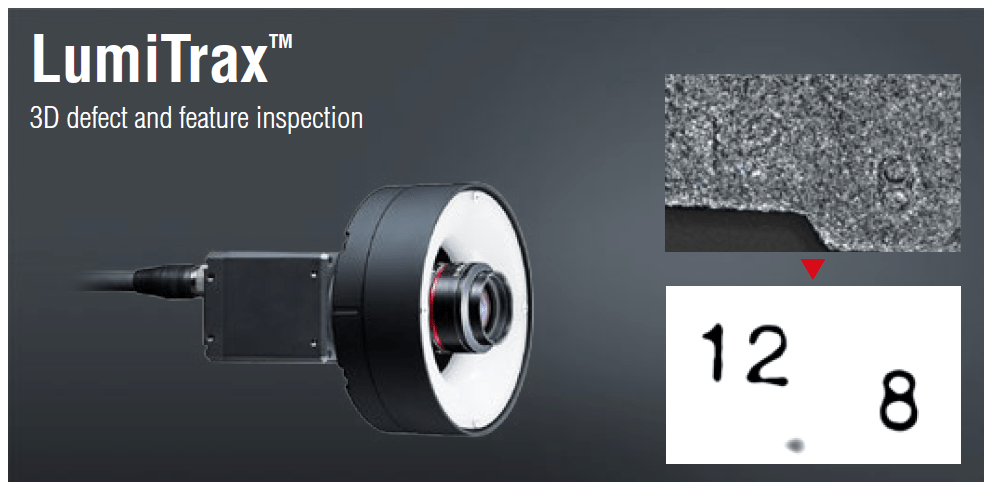

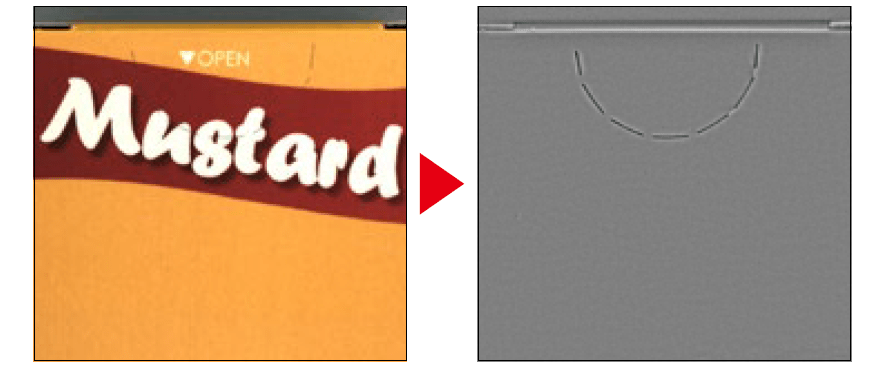

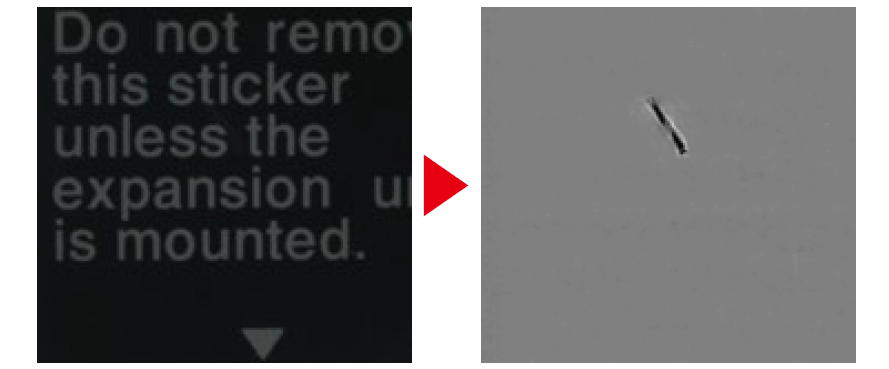

Stamped character vision inspection

The stamped characters, which are bumpy, are inspected while ignoring the characters printed on the package.

Examples include

Pharmaceutical packaging, Toothpaste Cartons, Variable Data and Product Security Features

Package opening perforation presence inspection

Chip inspection on a metal surface

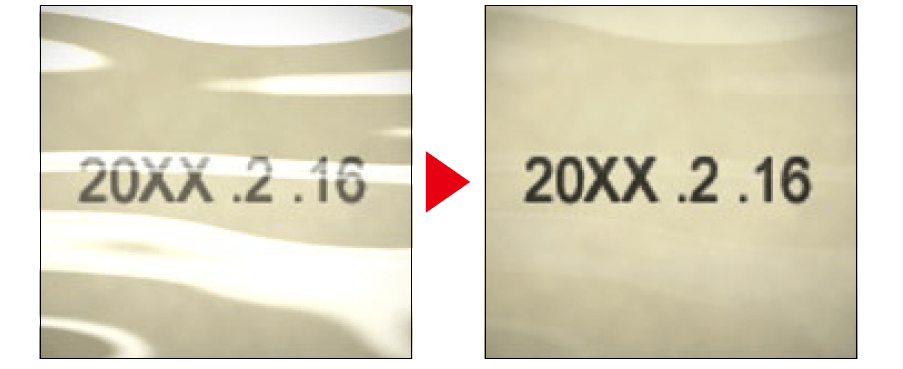

Printed character inspection on a film surface

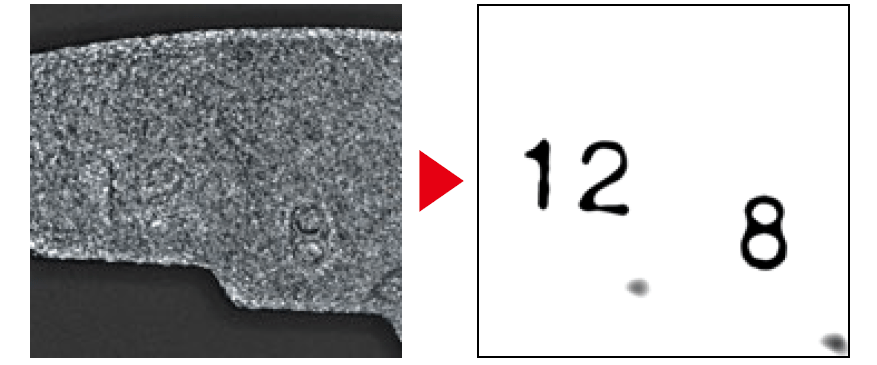

Metal casting surface carved seal inspection

Chip inspection on a printed surface

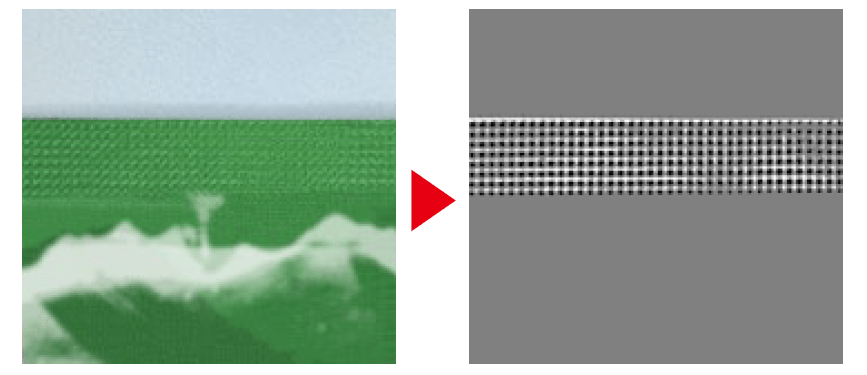

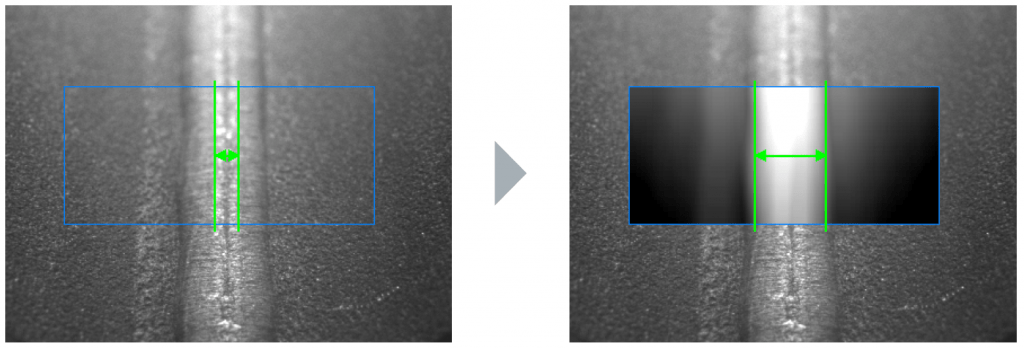

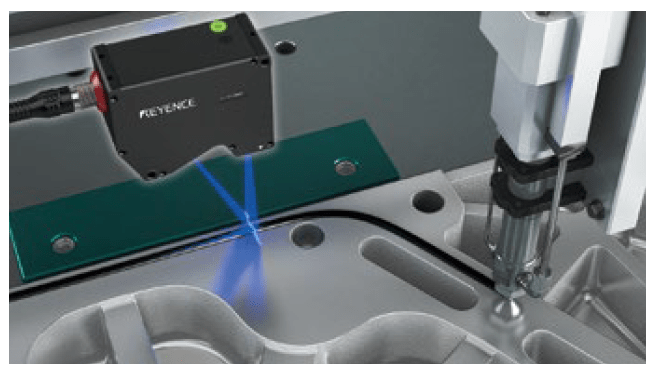

Packaging Integrity for the Food Industry - Heat seal width inspection

The roughness information of sealed parts, for which changes are difficult to detect by means of colour or shading, are captured and extracted. This system perfectly inspects heat sealed packaging such as tray sealing integrity inspection for ready meals and vertical bags sealers.

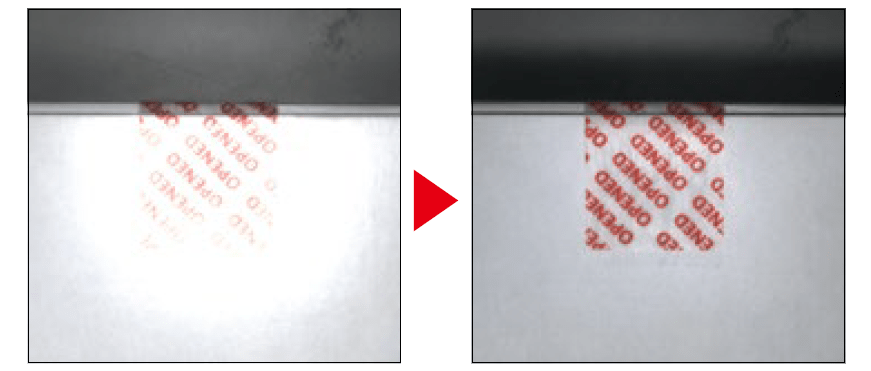

Tape presence inspection

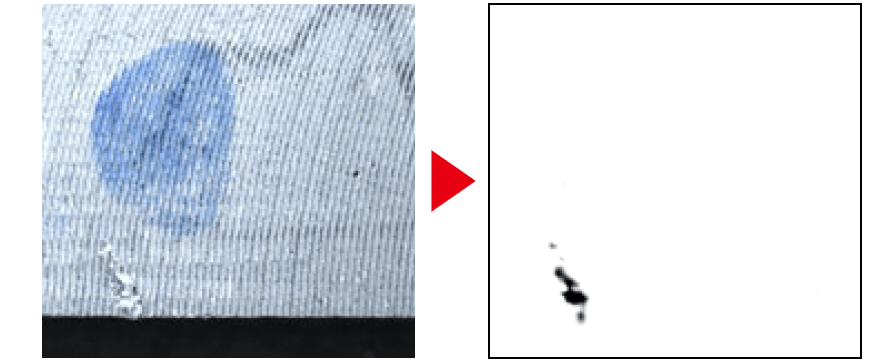

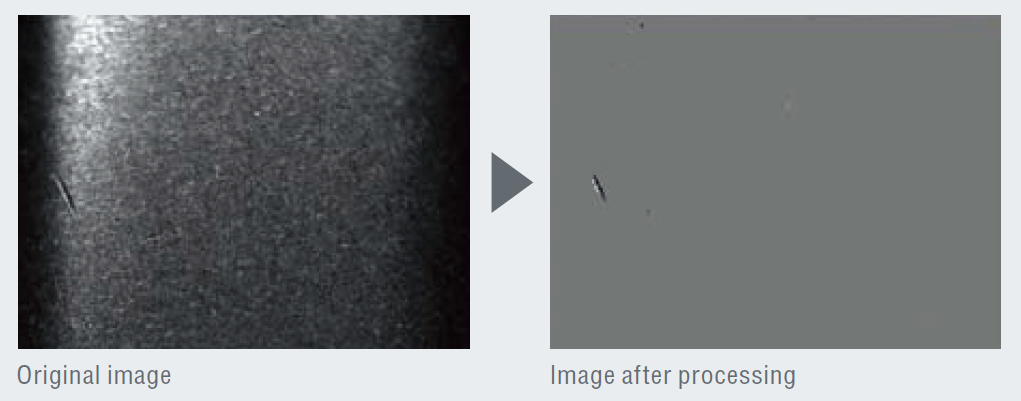

Foreign particle detection on the inside of a container

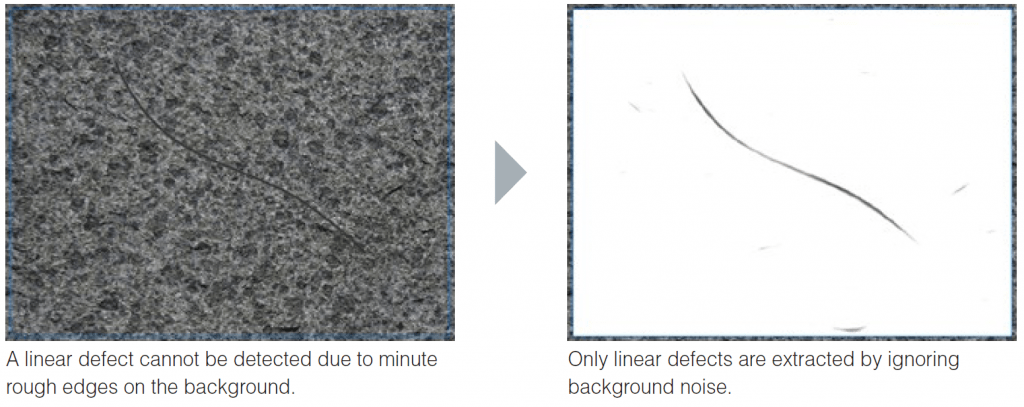

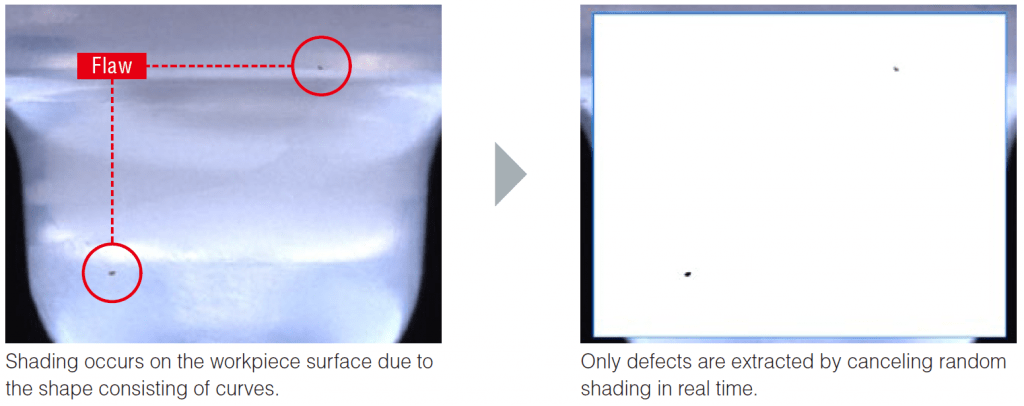

Cancel unwanted shading on metallic curved surfaces to enable stable machine vision performance

Surface roughness on plastic products canceled for stable flaw identification

Uneven texture on metal workpieces canceled for stable flaw identification

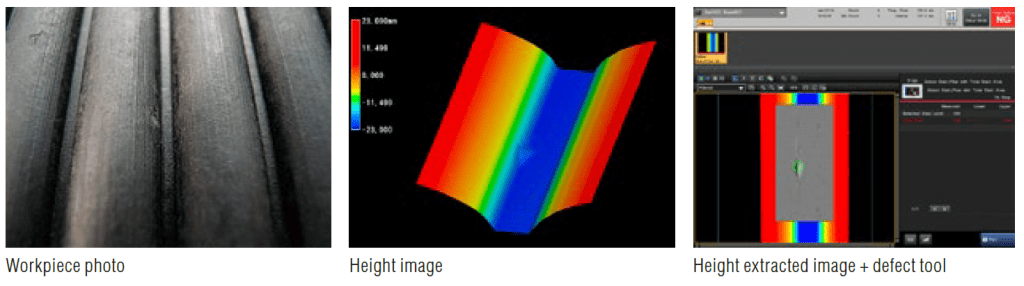

SCRATCH DEFECT INSPECTION

PLASTIC MOULD DEFECT DETECTION

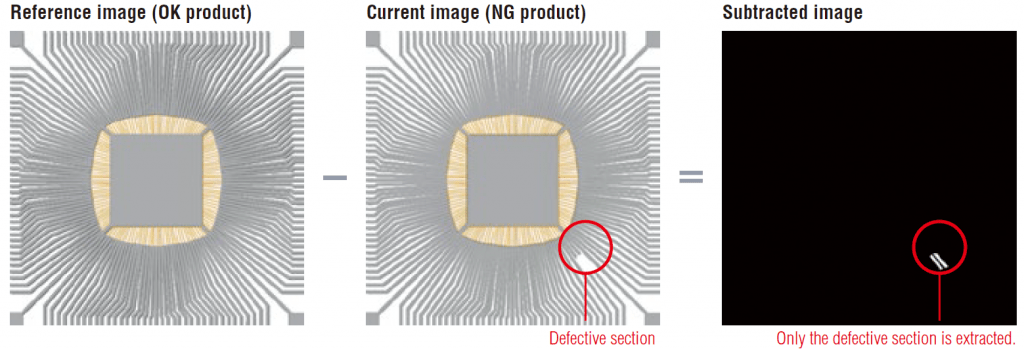

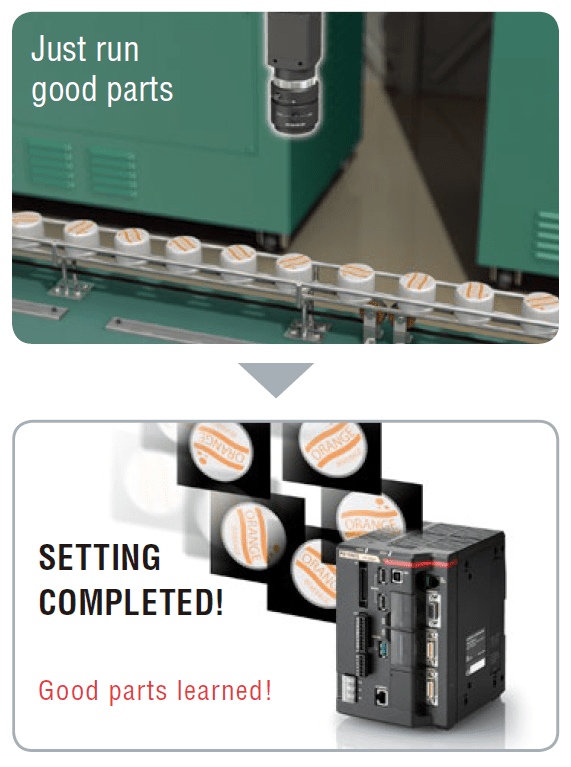

AUTO LEARN VISION SYSTEM UTILISING SUBTRACTION

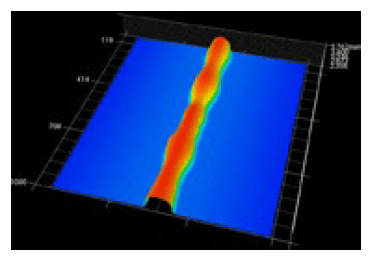

WIDTH INSPECTION FOR A WELDED PIPE SECTION

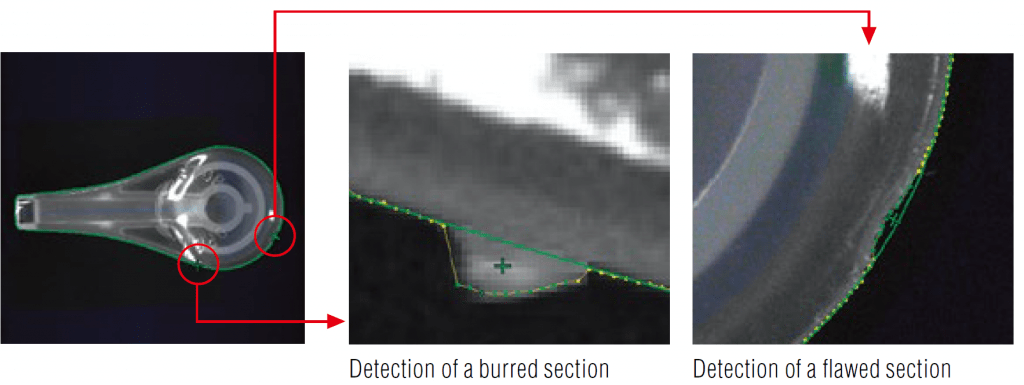

Edge defect inspection for burr and flaw inspection

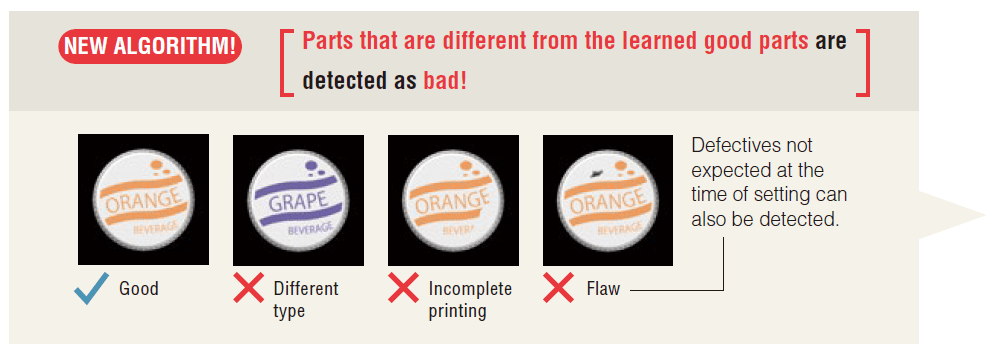

AUTO-TEACH INSPECTION TOOL

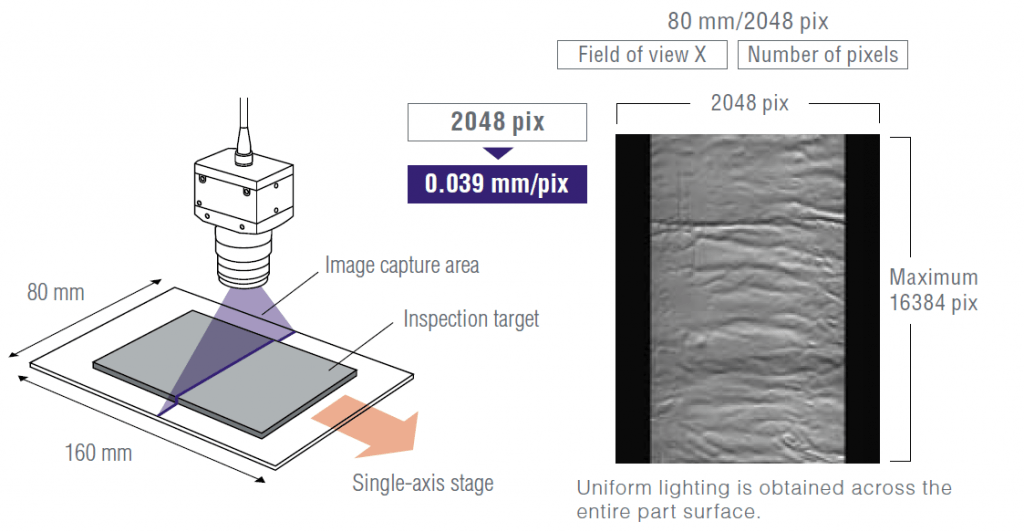

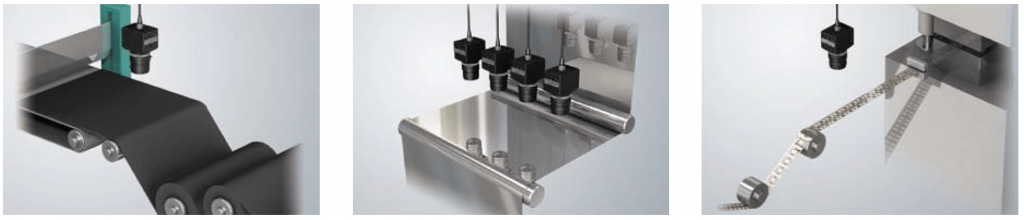

Line Scan Camera Vision Systems

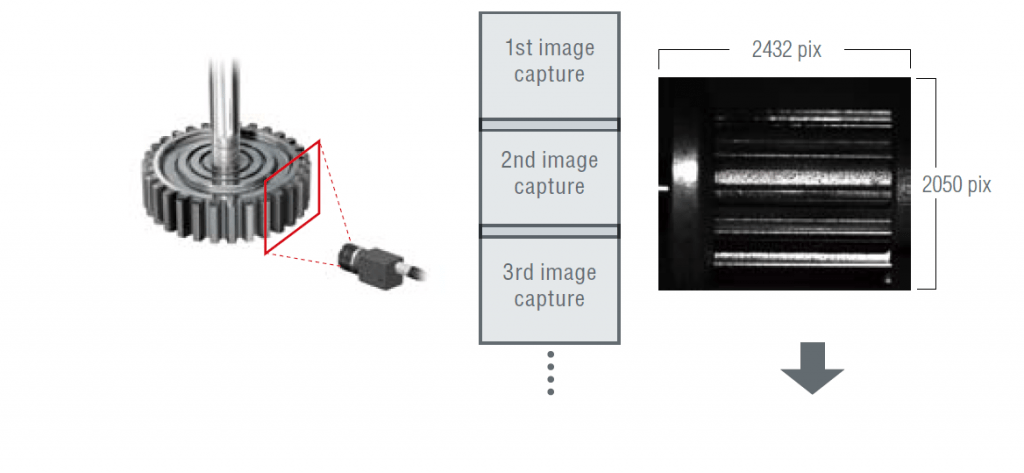

CYLINDER INSPECTION AREA CAMERA

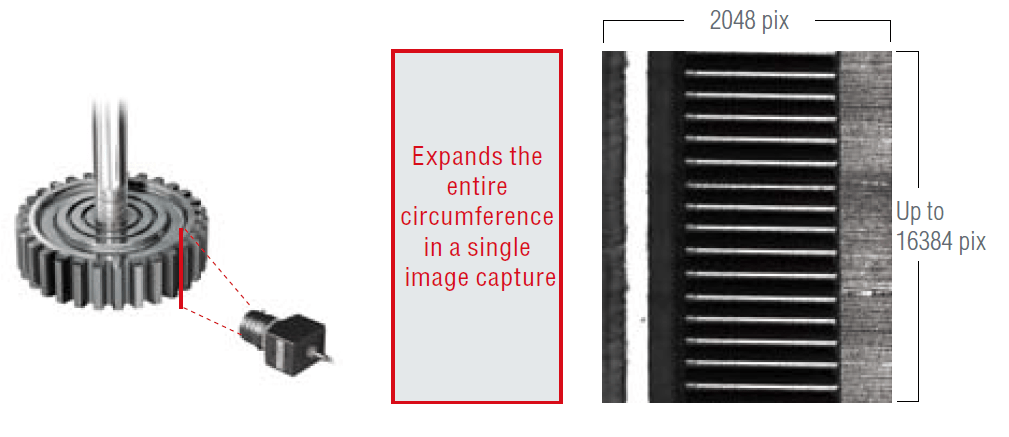

CYLINDER INSPECTION LINE SCAN CAMERA

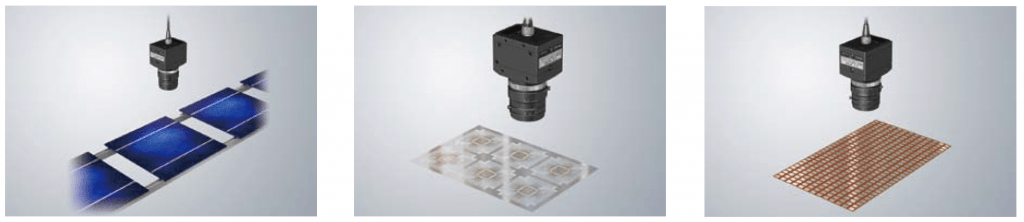

OTHER APPLICATION EXAMPLES:

Defects on blow moulded parts

Before blow moulding, the entire opening and body of the part can be inspected in one image when the part is rotated.

Visual inspection of a bearing

Achieves the visual inspection of curved surfaces, which is difficult to perform with an area camera, by capturing stabilised images with even lighting.

Visual inspection of a roller

Defects on the surface of long metal rollers can beinspected with high-accuracy using one or two linescan cameras.

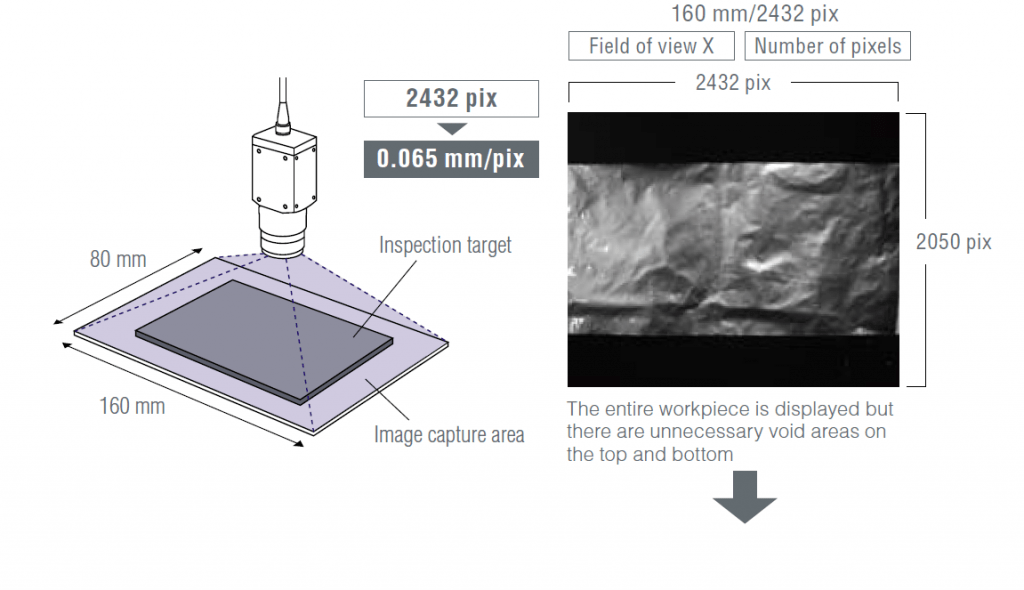

Line Scan Camera Vision Systems Foil Film Inspection

VISUAL INSPECTION OF ALUMINIUM FOIL WITH AREA CAMERA

VISUAL INSPECTION OF ALUMINIUM FOIL WITH LINE SCAN CAMERA

OTHER APPLICATION EXAMPLES:

Visual inspection of a roller

Defects on the surface of long metal rollers can beinspected with high-accuracy using one or two linescan cameras.

Visual inspection of lead frames

Visual inspection of the surface of plated lead frames and plate position inspection are accurately performed during transfer.

Visual inspection after printing electrodes

By using line scan cameras with line lights for targets that require a wide-field, uniform lighting is achieved and high-definition inspection is possible.

Dimensional inspection of a rubber sheet

Width measurement, which typically requires 2 area cameras on each edge, is performed with a single high resolution line scan camera, resulting in increased accuracy and reductions in cost.

Inspection of pinholes and dirt on a sheet

Achieves visual inspection of foreign objects, flaws, and pinholes on film or sheets on a high-speed production line.

accuracy.

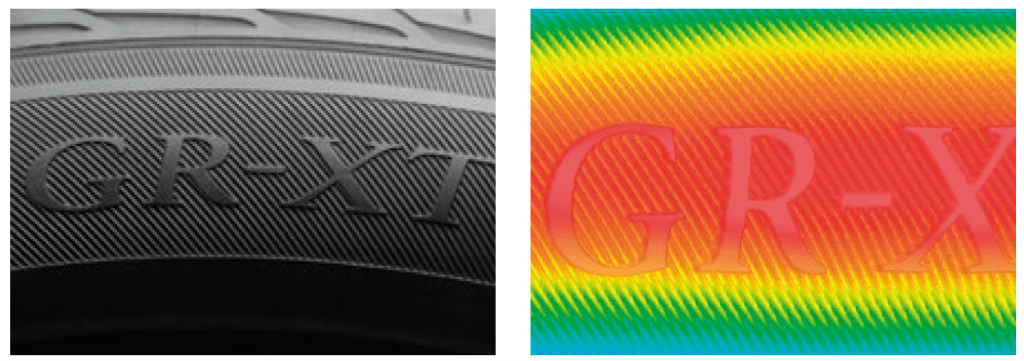

WORLD’S FASTEST! 3D INSPECTION & MEASUREMENT VISION SYSTEM

SAMPLING AT 64000 PROFILES/SEC

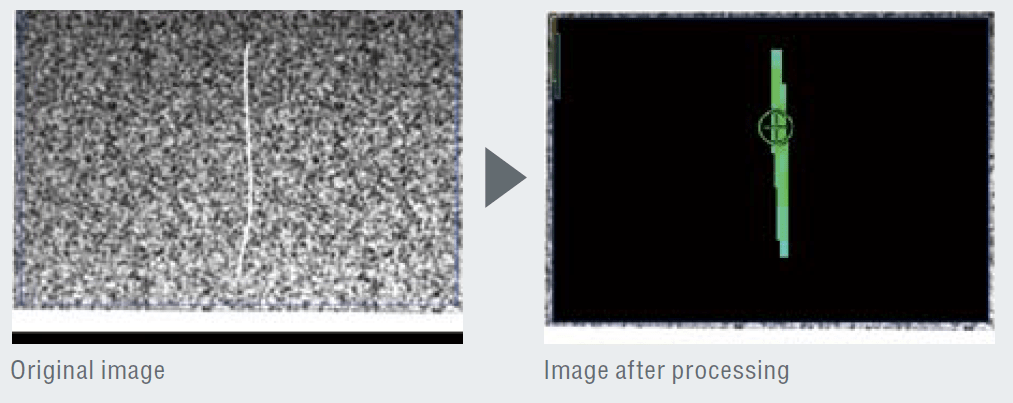

Low contrast between target and background? - Problem solved!

With an area camera, stable character recognition is difficult due to variations in background conditions and poorly defined stamped edges. Using 3D height information, the background can be distinguished clearly from characters

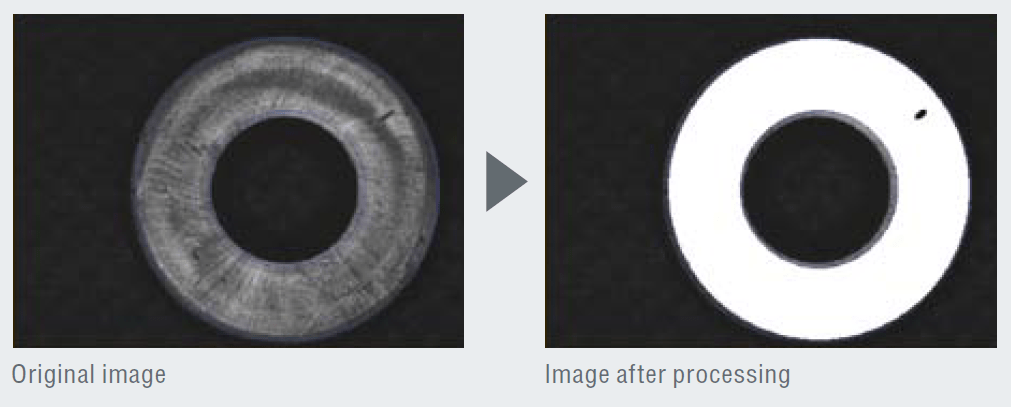

Defects missed on curved surfaces? - Problem solved!