- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

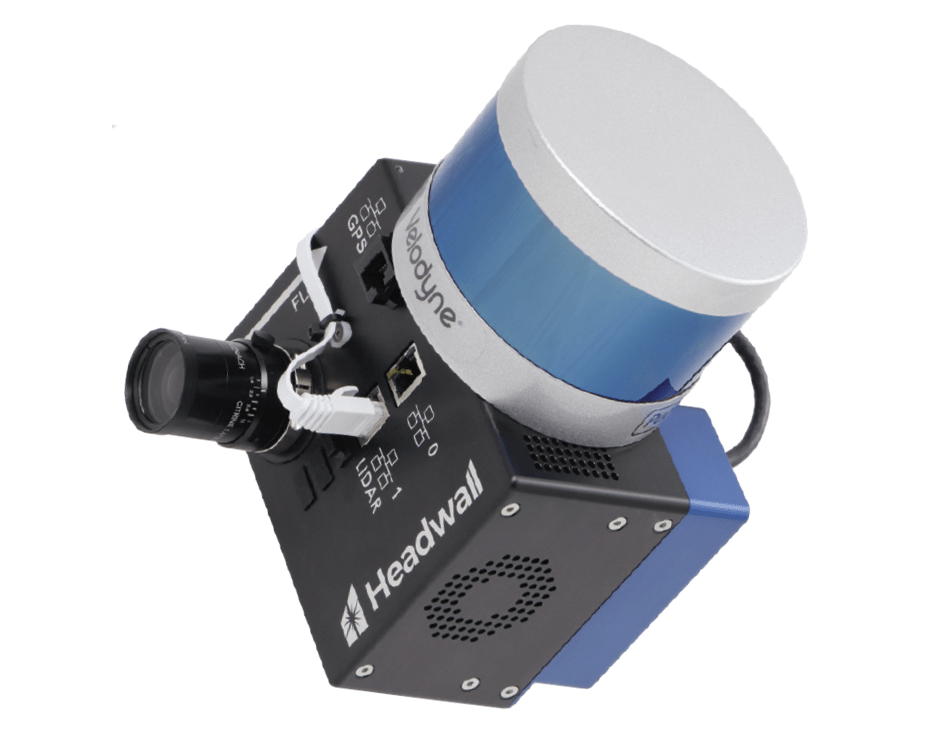

Hyperspectral Sensors Lab Field Industrial & Remote Sensing

At Automate and Control Ltd, we are committed to providing reliable machine vision inspection systems that help ensure the quality of your products. As a trusted supplier of automation solutions, we offer a wide range of solutions for various industries, including food and beverage, pharmaceuticals, cosmetics, and more.

FEATURES

• Compact hyperspectral sensor for push-broom scanning

• VNIR wavelength range (400 to 1,000 nm)

• 342 spectral bands, 1024 spatial pixels

• USB 3.1 connectivity

• 400 Hz maximum frame rate

• SDK for integration with National Instruments™ LabVIEW and for Python applications.

THE IDEAL PACKAGE FOR OEM SYSTEMS

Headwall’s original Nano-Hyperspec® and Hyperspec® MV took the hyperspectral imaging community by storm, becoming the best-selling systems of their kind. The MV.C VNIR™ sensor features higher spatial resolution and more spectral bands for customers who need an exceptionally small and light form factor for OEM instrumentation or for deloyment in challenging environments where space is at a premium. USB 3.1 interface provides power and fast transfer to your integrated data system. Standard C-mount allows a selection of lenses appropriate to your application.

To the right our turnkey lab kit including motion stage, lighting, full range sensor capability and software.

MV.C VNIR™ Compact VNIR Hyperspectral Imaging System for OEM

SPECIFICATIONS

Wavelength Range 400 – 1,000 nm

Spectral Bands 342

Spatial Pixels 1024

Camera Technology CMOS

Pixel Pitch 5.86 μm

Aperture f/2.5

Dispersion/Pixel 1.75 nm

Entrance Slit Width 20 μm

FWHM Slit Image 6 nm

Frame Rate (Sustained)1 400 Hz

ADC Bit Depth 12-bits

Spectrograph Design Aberration-Corrected Concentric

Interface USB 3.1

Weight (without lens) 0.3 kg / 10.6 oz

Dimensions (without lens) 64 x 50 x 38 mm / 2.5 x 2.0 x 1.5 in

Power Input 5 VDC

Operational Temp Range 0 – 50 °C / 32 – 122 °F

FEATURES

• Perfect for environmental monitoring, mining, and precision agriculture applications

• Factory integrated & flight tested

• Best-in-class SWaP (Size, Weight, and Power)

• VNIR wavelength range (400 to 1,000 nm)

• Built-in GPS-IMU, solid-state storage

• Available LiDAR for high-resolution DEM (Digital Elevation Model) creation & 3D point clouds

THE IDEAL SYSTEM FOR VNIR REMOTE-SENSING

UAV MISSIONS

Headwall’s original Nano-Hyperspec® took the remote-sensing community by storm, becoming the best-selling system of its kind. The next-generation Nano™ HP features improved spatial resolution, as well as a greater number of spectral bands in an exceptionally small, light, and power-efficient form factor.The Nano HP can be purchased as a payload for integration onto compatible UAVs, and also as part of integrated “turnkey” systems that include the drone. These include the DJI Matrice 300 RTK1, DJI Matrice 600 Pro, as well as the FreeFly Alta X that is made in the USA and supports NDAA-compliance.Optional sensors and accessories such as LiDAR and thermal-imagers2 can be incorporated into payloads suitable for your needs.

Portable & Robust

The Headwall Nano HP comes with a high-performance GPS/IMU and enables Light Detection and Ranging (LiDAR) to be added as an integral module, so that a Nano HP with LiDAR is actually lighter and smaller than a similarly equipped original Nano-Hyperspec!

Fixed- or gimbal-mount configurations are available, depending on the parameters of your payload. The platform-agnostic, browser-based HSInsight™ interface makes setting up your Nano HP easy.

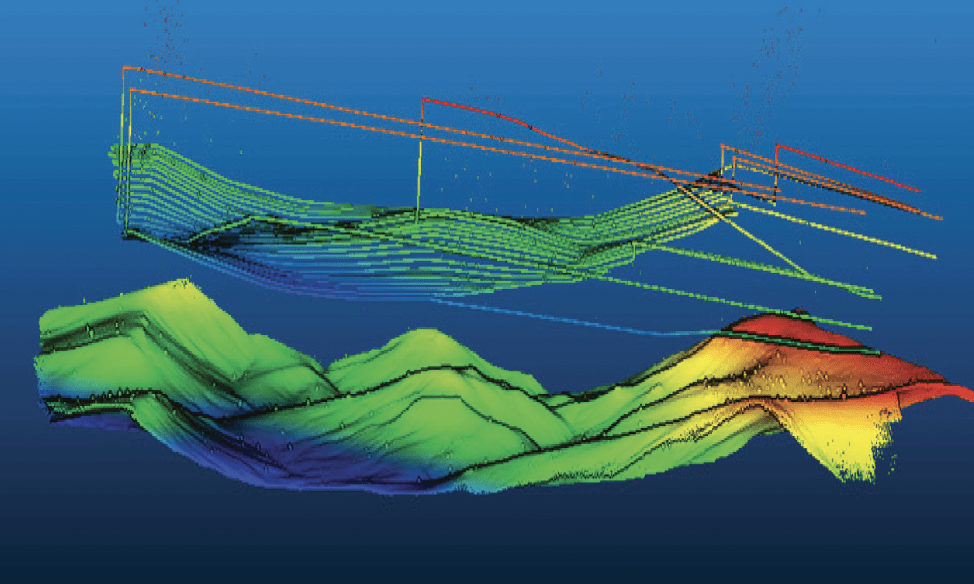

The images to the side are 3D point clouds generated from an optional LiDAR sensor that was part of the payload during a hyperspectral UAV mission to Cuprite, Nevada by a team from Headwall and the University of Arizona. LiDAR allows high-resolution digital elevation models (DEMs) to be created to enable more precise flight operations as well as more accurate orthorectification of the hyperspectral imaging data.

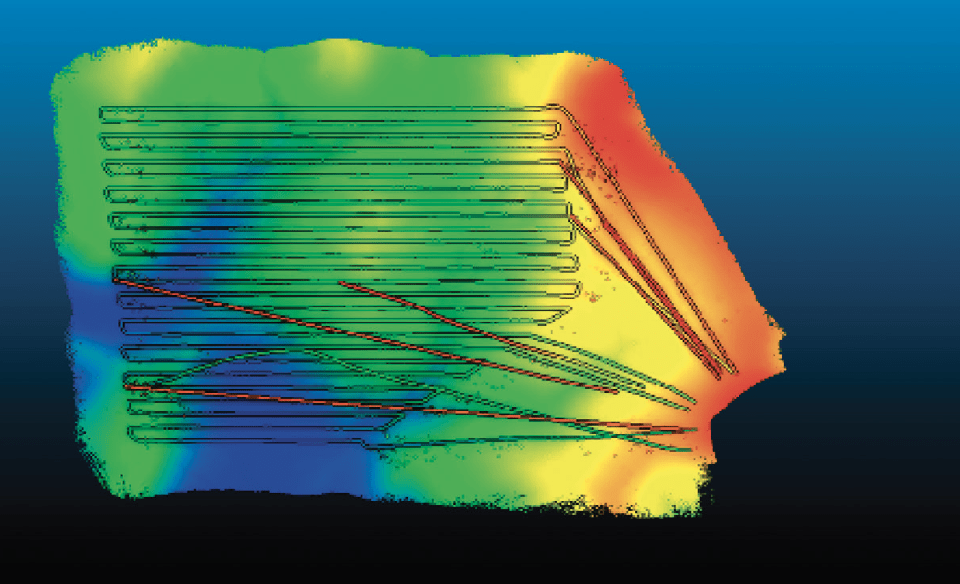

Headwall UAV systems are programmed to follow terrain at a constant altitude above ground level. The hyperspectral data that is captured from the air is post-processed and orthorectified so that a consistent nadir view of the mission area is achieved.

You can see on the left that the aircraft enters and departs the capture area along straight lines. While inside the ‘capture polygon’ designated as part of the flight plan, the hyperspectral sensor is activated and a “lawnmower” pattern is flown as shown in the image on the right.

Nano HP™ Compact VNIR Hyperspectral Imaging System for Remote-Sensing

SPECIFICATIONS

Wavelength Range 400 – 1,000 nm

Spectral Bands 342

Spatial Pixels 1020

Camera Technology CMOS

Pixel Pitch 5.86 μm Aperture f/2.5

Dispersion/Pixel 1.76 nm

Entrance Slit Width 20 μ

Spectral FWHM 6 nm

Frame Rate (Sustained)3 250 Hz

ADC Bit Depth 12-bits

Spectrograph Design Aberration-Corrected

Digital Interface GigE

GPS/IMU Internally Mounted High-Performance with PPK4

Data Storage on Payload 480 GB Solid-State

Weight (without / with LiDAR) 1.05 kg (2.32 lbs) / 1.73 kg (3.81 lbs)

Base Dimensions (without / with LiDAR) 132 x 102 x 73 mm (5.2 x 4.0 x 2.9 in) / 132 x 175 x 99 mm (5.2 x 6.9 x 3.9 in)

Power without LiDAR (typical) 14.4 W

Operational Temp Range 0 – 40 °C / 32 – 104 °F

Storage Temp Range -20 – 60 °C / -4 – 140 °F

– Onboard Runtime Spectral Classification

– Powerful Embedded CPU/GPU

– Direct Output of Actionable Results

– Integration with Industrial Control Systems

– Simple Installation

– Web User Interface

– IP 66/67 Ingress Protected for Industrial Use

The award-winning Hyperspec® MV.X introduces to the industry a fully integrated hyperspectral imaging system that enables users to realize the value of spatial and spectral information in industrial applications like automated sorting, quality inspection, authenticity verification, and process monitoring.

Hyperspec® MV.X VNIR

Hyperspec® MV.X

Wavelength Range 400-1000 nm

Spatial Bands 1020

Spectral Bands 301

Spectral Sampling 2.0 nm/pixel

Spectral FWHM 6 nm

System F/# F/2.5

Optical Design Aberration-Corrected Concentric

Field of View Angular

Instantaneous 24mm Focal Length Lens 14.20° 0.014°

16mm Focal Length Lens 21.16° 0.21°

Other Lenses Available

Bit Depth 12 bit

Interfaces GenICam WebSocket MQTT* RS232/422* 5V TTL*

Data Outputs

GenICam – Classified Image (Class ID/Color/Grayscale), Object Metadata, Hyperspectral

WebSocket – Classified Image (Class ID/Color/Grayscale), Object Metadata, Hyperspectral

MQTT – Object Metadata, Process Variables

ENVI – Hyperspectral Data on Local SSD

Ports RJ45 (GigE) x2 D-Sub 26 Pin (GPIO)

Software Web User Interface for system configuration and control.

On-board classification modules available.

Embedded Processing CPU/GPU

Camera Sensor Technology CMOS

Memory, Storage 8GB RAM, 128GB SSD

Input Voltage 12-30V DC

Max Power Consumption < 42 W

Dimensions (L x W x H) 255 x 136 x 136 mm / 10.0 x 5.4 x 5.4” Weight with 24 mm Lens 3 kg / 6.6 lb

Ingress Protection (IP) Rating IP66, IP67

Operating Temperature Range 0 – 50°C / 32 – 122°F

Storage Temperature Range -10 – 60°C / 14 – 140°F

Hyperspectral Turnkey Remote Sensing Solutions

Our machine vision inspection systems are designed to detect defects, measure dimensions, check for completeness, and perform various other quality checks on your products. With our advanced systems, you can be confident that your products meet the highest standards of quality and safety.

Our machine vision inspection systems are capable of inspecting a wide range of products, including bottles, cans, boxes, cartons, labels, and more. We also offer customized solutions to meet the specific needs of your industry and products.

Benefits of Using Machine Vision Inspection Systems:

Enhanced Product Quality: Our machine vision inspection systems are designed to detect even the smallest defects, ensuring that your products meet the highest standards of quality.

Increased Efficiency: By automating the inspection process, our systems can help you increase productivity and reduce costs associated with manual inspection.

Improved Compliance: Our systems are designed to comply with regulatory standards, ensuring that your products meet the requirements of various regulatory bodies.

Enhanced Customer Satisfaction: By ensuring the quality and safety of your products, our machine vision inspection systems can help you build customer trust and loyalty.

At Automate and Control Ltd, we have a team of experienced professionals who can help you choose the right machine vision inspection system for your business. We also offer installation, training, and support services to ensure that your system is up and running smoothly.

Contact us today to learn more about our machine vision inspection systems and how they can help you improve the quality and safety of your products.

Automate and Control Ltd: Your Partner for the World’s Most Advanced Machine Vision Inspection Systems

At Automate and Control Ltd, we provide cutting-edge machine vision inspection systems that harness the power of Artificial Intelligence (AI), Machine Learning (ML), and Hyperspectral Imagery. These advanced technologies enable our systems to provide unparalleled accuracy and precision in detecting even the slightest defects and abnormalities in your products.

Our machine vision inspection systems use AI and ML algorithms to analyze vast amounts of data and learn from it, allowing the system to continuously improve and adapt to changing conditions. This helps us provide reliable and accurate inspection results, which are critical to maintaining the quality and safety of your products.

In addition to AI and ML, our machine vision inspection systems also use Hyperspectral Imagery, a powerful technology that allows for precise identification and characterization of materials based on their unique spectral signature. This enables our systems to detect even the most subtle differences in color, texture, and composition, making them ideal for industries with high standards of quality, such as food and beverage, pharmaceuticals, and cosmetics.

With our advanced technology, we are proud to offer the world’s most advanced machine vision inspection systems. Our systems are designed to deliver unmatched accuracy, efficiency, and reliability, helping you ensure the quality and safety of your products.

At Automate and Control Ltd, we have a team of experienced professionals who can help you choose the right machine vision inspection system for your business. We also offer installation, training, and support services to ensure that your system is up and running smoothly.

Contact us today to learn more about our advanced machine vision inspection systems and how they can help you improve the quality and safety of your products.

Automate and Control LTD not only provide Industry 4.0 end to end solutions but manufacture bespoke packaging and process equipment enabling your business to evolve with the revolution.