- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

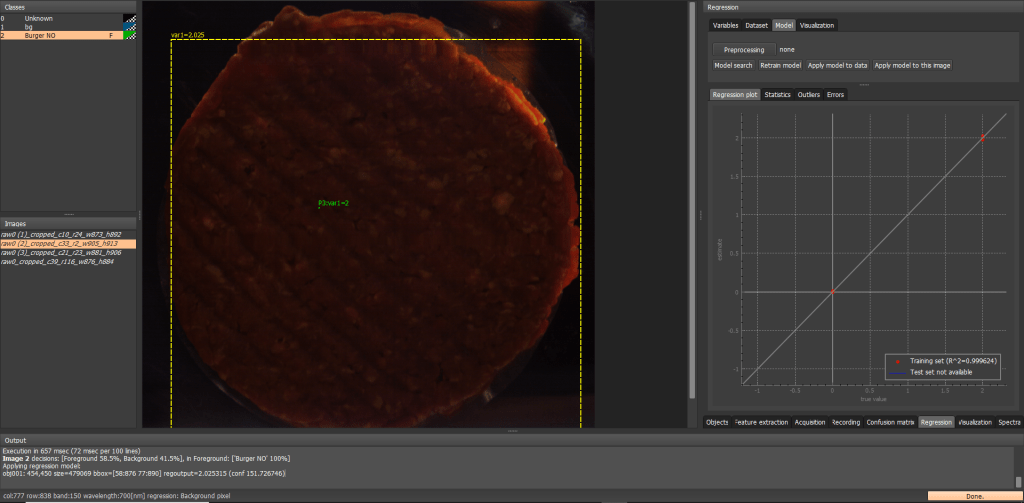

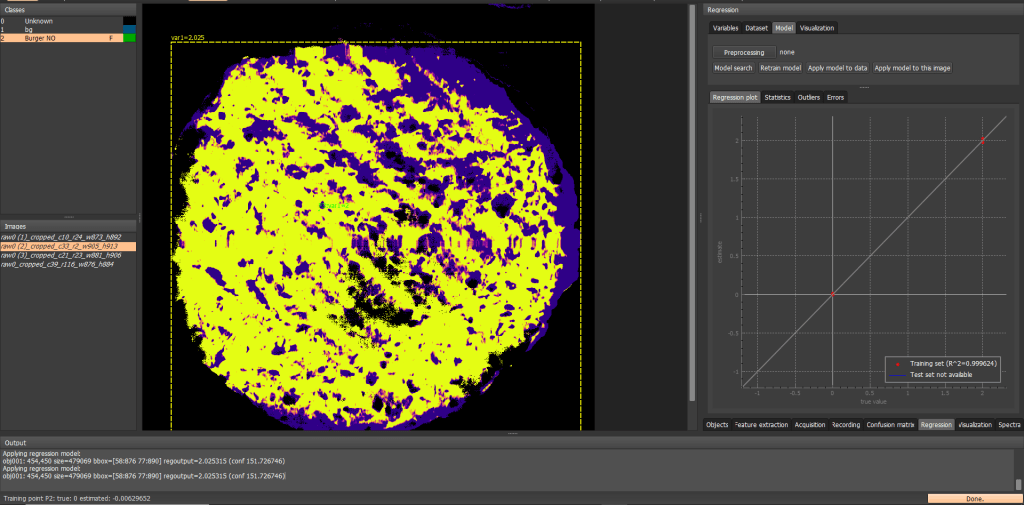

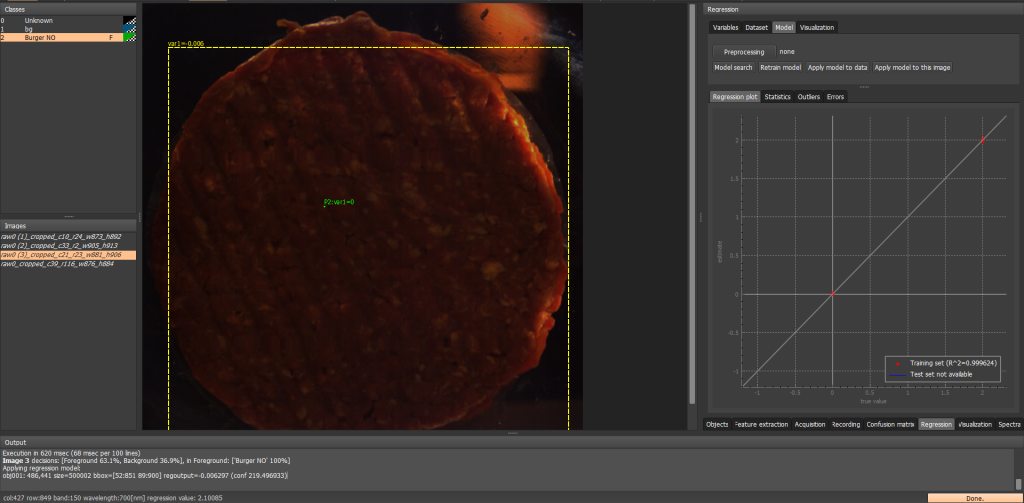

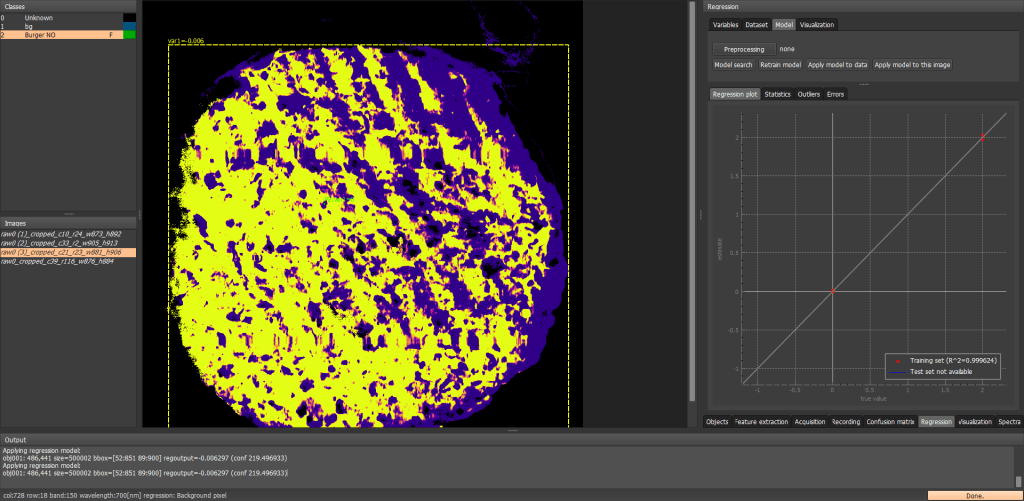

bioClass® Quality Inspection System detecting low density plastics in processed foods

Low Density Polymer Detection

In the production of intricate multi-ingredient foods, there exists an inherent concern, despite the utmost diligence of manufacturers: the potential for packaging contaminants to infiltrate the final product.

Our cutting-edge system possesses the capability to identify chemical irregularities stemming from foreign polymers present within the product’s chemical composition. This identification process occurs in real-time, and it’s entirely non-invasive. Consequently, contaminated products are promptly excluded from your production lines.

In today’s food processing facilities, the use of rubber gloves and plastic bags is commonplace, introducing an additional layer of risk into the production process. The demonstration below showcases the same burger passing through our system, both with and without contamination. The numeric value within the enclosed box ranges from 0 to 2, with 0 signifying an absence of contamination and 2 denoting the detection of contaminants.

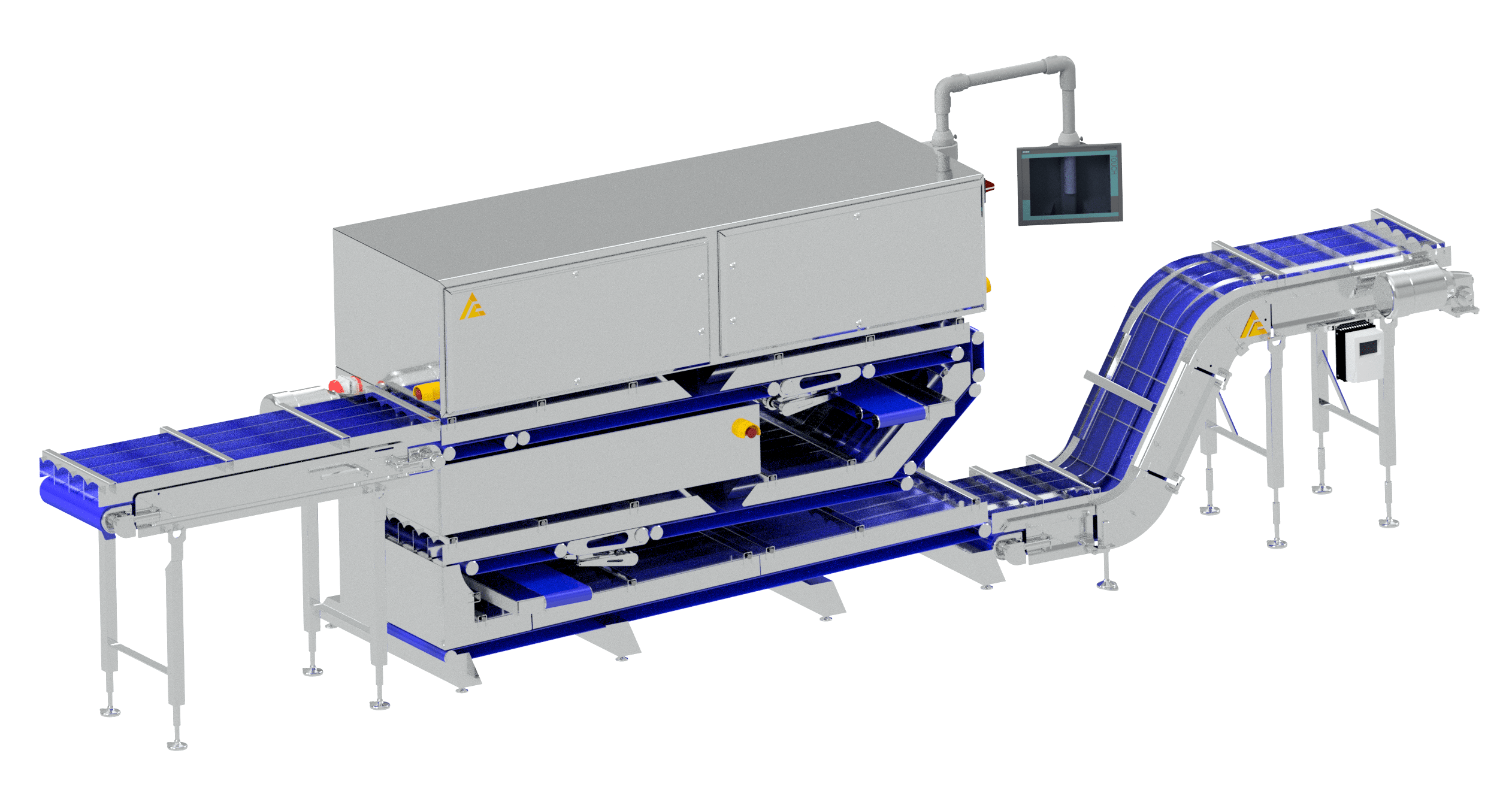

bioClass® Hyperspectral Inspection System

Specification

bioClassu00ae is a high speed system capable of inspecting and automatically rejecting each non-conformance for rework or rejection.

Brand Protection

Whilst X-ray and metal detectors ensure consumer safety, the bioClass is a complementary quality inspection technology that guarantees consistent product quality. With the modern age of social media, one bad consumer experience of your products can have a rapid negative effect on your companies brand.

Flexibility

One size does not suit all, we understand our customers have existing production lines and the addition of a new piece of inspection equipment won't always fit easily. Automate and Control LTD have the capability to build bespoke solutions to fit your current processing setup.

Functionality

High speed nut quality inspection system, designed to reject the following non-conformances. Any component which does not have the same chemical signature as the nut we are inspecting including product with, bacterial Ggowth and foreign matter.

Automate and Control LTD not only provide Industry 4.0 end to end solutions but manufacture bespoke packaging and process equipment enabling your business to evolve with the revolution.