- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

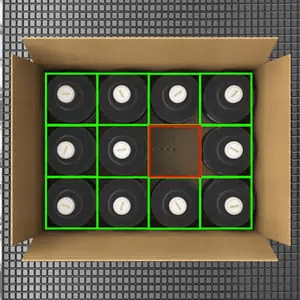

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

- Vision Inspection and Sorting

- Agrocultural Systems

- Colour Vision Systems

- Label Inspection System

- Seal Check Inspection

- Vision Systems – Applications

- Vision Systems – Foreign Matter Detection

- AI Code Reading Systems

- Vision Sensor Application Examples

- Face Mask Inspection System

- Profile Flaw Detection

- Sachet Detection in Pots

- Detection of Missing Products in Boxes

- Batch – Date Code Verification

- Missing Label Detection

- Loose Cap Detection

- Under Fill Detection

- Printed Expiration Date Verification

- Attached Straw Detection

- Hot Melt Detection on Cartons

- Chemical Vision Inspection (Hyperspectral)

- bioClass® Process Control Homogeneous Dry Powders

- bioClass® Same Colour Foreign Matter Detection in Rice

- bioClass® Herb Quality and Purity Inspection

- bioClass® Muscle Abnormalities Woody Breast Detection

- bioClass® Pathogen detection

- Food Fraud Detection

- bioClass® for Food Inspection

- bioClass® Quality Inspection Pistachio

- bioClass® Quality Inspection Almonds

- bioClass® Quality Inspection System – POULTRY

- bioClass® Date Grading System

- bioClass® Food Inspection – Non-destructive Chemical Analysis

- bioClass® Quality Inspection Detection of Low Density Plastic in Processed Meats Foods

- bioClass® Hyperspectral Quality Inspection and Sorting Systems

- Hyperspectral Applications

- SORTING MACHINES

- 2024 Vision System Applications

- Video

- Posts

- Posts

- Articles

- Sustainability from bioClass®

- Never seen before BLACK HOLE imaging from NASA

- bioClass® Non-destructive Food Contamination Detection

- COVID-19 Hitting Reset on the Fast Food and Ready to Eat Sector of the Poultry Industry

- Eliminate Machine Crashes

- Using vision systems for food quality control

- Using Industrial Vision to Reject Burnt Food on a Production Line

- Archive

- Contact

- SERVICE / PARTS

Automated Inspection Systems: Enhancing Quality and Efficiency

In the modern manufacturing landscape, quality and efficiency are paramount. Companies constantly seek innovative ways to improve product quality, reduce costs, and streamline operations. Automated inspection systems, particularly those utilizing machine vision technology, have emerged as crucial tools in achieving these objectives. These systems enhance manufacturing performance by detecting contaminants, measuring dimensions, and verifying product completeness, ensuring that only products meeting the highest standards reach the market.

The Role of Automated Inspection Systems

Automated inspection systems leverage advanced imaging technology to evaluate products in real-time. Unlike manual inspection, which can be time-consuming and prone to human error, automated systems provide consistent, accurate, and rapid assessments. Key components of these systems include high-resolution cameras, lighting, and sophisticated software algorithms that analyze visual data to detect defects and deviations from set standards.

Vision

SYSTEMS

Detection of Contaminants

– **Food and Beverage Industry:** In sectors like food and beverage, ensuring that products are free from contaminants is crucial for consumer safety and regulatory compliance. Automated inspection systems can detect foreign objects, such as metal fragments or plastic pieces, ensuring that contaminated products are identified and removed from the production line.

– **Pharmaceuticals:** In pharmaceuticals, maintaining product purity is essential. Automated systems inspect tablets and capsules for contaminants, preventing compromised medications from reaching patients.

2. **Measurement of Dimensions**

– **Precision Engineering:** In industries where precision is critical, such as aerospace and automotive, ensuring that components meet exact specifications is vital. Automated inspection systems measure dimensions with high accuracy, identifying any parts that do not conform to the required tolerances.

– **Packaging:** Ensuring that packaging is uniform and meets size specifications is important for both aesthetics and functionality. Automated systems measure packaging dimensions, ensuring consistency and reducing material waste.

3. **Verification of Product Completeness**

– **Assembly Lines:** On assembly lines, verifying that each product is complete and correctly assembled is essential. Automated inspection systems check for the presence and correct placement of components, ensuring that defective products are caught early in the process.

– **Consumer Goods:** In the production of consumer goods, ensuring that products are complete and functional before they reach the market is critical for maintaining brand reputation. Automated systems verify product completeness, reducing the risk of customer dissatisfaction and returns.

**Benefits of Automated Inspection Systems**

The integration of automated inspection systems offers several significant benefits:

– **Improved Product Quality:** By identifying defects and contaminants early, automated inspection systems ensure that only high-quality products reach consumers.

– **Cost Reduction:** Automated systems reduce the need for manual inspection, lowering labor costs and minimizing the financial impact of defective products through early detection.

– **Enhanced Efficiency:** These systems operate continuously and consistently, speeding up the inspection process and allowing for higher production rates without compromising quality.

– **Data Collection and Analysis:** Automated inspection systems collect vast amounts of data, which can be analyzed to identify trends, optimize production processes, and predict maintenance needs.

**Case Studies**

1. **Automotive Industry:** A leading automotive manufacturer integrated automated inspection systems into its production line, resulting in a 20% reduction in defective parts and a 15% increase in overall production efficiency.

2. **Food Processing:** A major food processing company implemented machine vision inspection systems to detect contaminants, leading to a 30% decrease in product recalls and significant cost savings in waste management.

**Future Trends**

The future of automated inspection systems lies in the integration of artificial intelligence (AI) and machine learning (ML). These technologies will enhance the capability of inspection systems to learn and adapt, improving accuracy and efficiency over time. Additionally, the development of more sophisticated sensors and imaging technologies will expand the range of detectable defects and contaminants.

**Conclusion**

Automated inspection systems are transforming the manufacturing industry by enhancing quality and efficiency. Through the detection of contaminants, precise measurement of dimensions, and verification of product completeness, these systems ensure that products meet the highest standards. As technology continues to advance, the capabilities of automated inspection systems will only grow, further driving improvements in product quality and manufacturing efficiency.

—

For more articles and in-depth analysis on automation and control systems, visit [Automate and Control](https://www.automateandcontrol.com).